Many quilters are working hard and enjoying themselves, making the block(s) for the Crazy Colors Mystery Quilt 2017 project. It is wonderful to see so many pictures, but also to answer a lot of questions. One of the most frequently asked questions is what needles you can use to be able to work with different threads. Quilters are telling me that they don’t like to change needles too much. Or ask me why their threads are breaking or fraying, even when they are using the same (kind of) needle for many years… and why people are always talking about the importance of using the right needle.. isn’t one type of needle enough?

Let me start at the beginning: needles for the domestic sewing machine are available for many different ‘tasks’. Ever since the sewing machine was available for working at home, around 1850 (even though such a machine was as expensive as a midrange car today), the developement of needles kept up with the developement of sewing machines. Machines were improved, the straight stitch was invented (before that, sewing machines worked with the chain stitch), many functions were added. And the needles were developed along with them. A complete and major industry with research and tests for better products.

There are needles made for special brands of sewing machines, needles that are made by companies that are manufacturing threads and also universal needles. That means many type of needles, offen for different purposes. When purchasing your sewing machine, your dealer often provides one or two sets of needles, mostly from the brand of your new machine, sometimes Schmetz needles (an important manufacturer of machine needles). All fine needles, all with their own charactaristics.

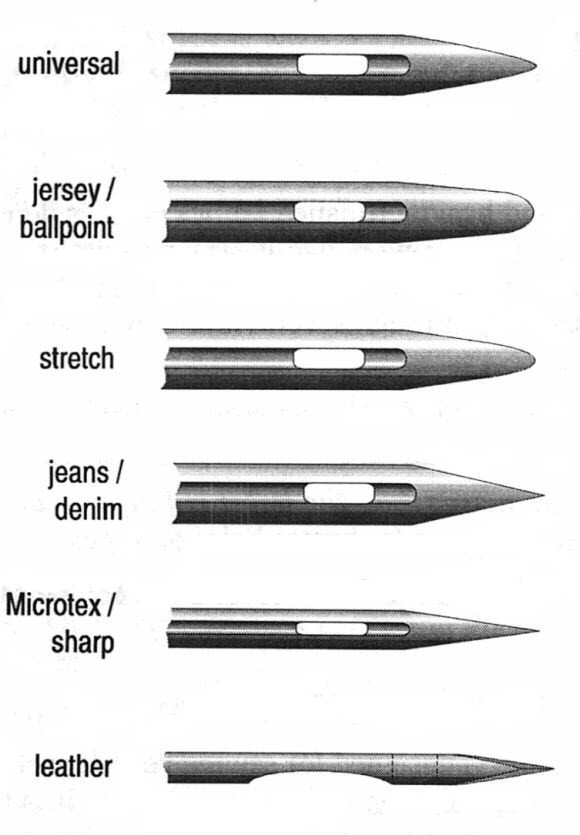

There are needles for sewing, for working with thick fabrics, thin fabrics, for embroidery, for lace, for quilting, for metallic threads… many times experts advise to choose a needle with the fabric, others advise to choose them with the threads. And they all are right, but even then there is so much to choose from. Check the picture above, how many different shapes of points and eyes there are with needles, but also different grooves (for guiding the thread to the eye). A lot of time and effort has been put in testing to present the best quality of needles to make sure the owner of the sewing machine will get the best results.

We all know that needles wear, and that a ‘regular’ needle is good for up to 8 hours of work. Yes: 8 hours! That is not the time of being set in the machine, but the actual working time, when a thread passes through the needles at high speed, and the point of the needle goes up and down through fabric or a sandwich – sometimes with a 1000 stitches per minute! After 8 hours, the needle is worn out, point blunt, blurr in the eye and even the needle can be bent, wich could be the reason why the thread on top of your machine will fray or break.

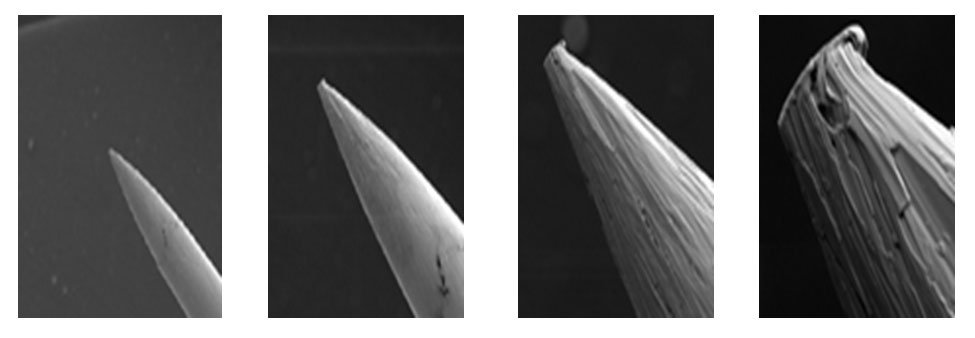

Just look at the picture above, taken with a electron microscope. The left picture shows a new needle. Further to the right the needle is starting to wear, point dull and striations on the needle, and eventually a burr on the point. Now for those who don’t own a electron mictroscope (who does?!); how do you know if a needle needs to be replaced:

Just look at the picture above, taken with a electron microscope. The left picture shows a new needle. Further to the right the needle is starting to wear, point dull and striations on the needle, and eventually a burr on the point. Now for those who don’t own a electron mictroscope (who does?!); how do you know if a needle needs to be replaced:

Check the following: shredded or broken threads, skipped Stitches, puckered fabrics, damaged fabrics, uneven seams, popping or clunking sound from sewing machine.

How can you tell if the point of a needle is still sharp without a burr? Pull the point of the needle gently over your thumnail: if a groove appears in your nail, the point is damaged. It can be bent or worn. And please, don’t try to smoothen it with sand paper, because that doesn’t work (and believe me, someone tried this and asked me if she did allright….)

How can you tell if the eye of a needle is still smooth? The eye can have a burr or wear when too much thread has passed through, or if a burr was left after manufacturing the needle and the eye was not smoothed the right way. Ask if someone holds the needle for you, then take a thread that is fragile (for instance metallic thread) and pull the thread through the eye, gently but fast, on all sides. If the thread frayes or breaks, the needle needs to be replaced: your work will improve.

So far so good. But even if you have checked the above, how do you choose the right needle for making decorative stitches with all the wonderfil machine threads that are available today. Do you have to change needles all the time when changing threads? The answer is yes if you have different kind of needles, but NO if you use a Topstitch needle – and the best one for me is the one I am working with: the Superior Titanium-coated needle.

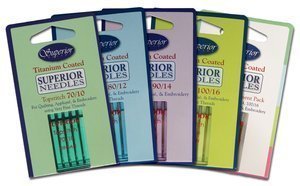

Superior Titanium-coated Topstitch needles are machine needles with a thin layer of Titanium-nitride, which make the needle stronger in terms of tensile strenght. It keeps the point sharper for a longer time. Titanium-nitride is a very tough substance with excellent abrasion resistance. The needles of Superior come in 4 different sizes, of which the most used are 70/10 (for thin threads), 80/12 (all medium size threads) and 90/14 (for all threads, even thicker ones and metallic threads). These needles last longer than ‘regular’ needles, up to 5 or 8 times. They are not cheap, but worth every penny you are spending on them.

Now for some technical stuff: how are Superior Topstitch needles made? High-strenth steel is straigtened and cut to length. After that the cut steel is shaped, forming the shank and blade of the needle. The eye is stamped out and the groove is milled. Then the point is sharpened and the eye is polished. The needles are bathed after that in a special solution to remove irregularities, and then heated in an oven to harden the metal. Then they are plated with Chrome for smooth texture and friction resistance. And last but not least they are coated with Titanium-nitride for advanced abrasian-resistance and extended life. So you see, a lot has been done to make a strong and high-quality needle.

Tests have shown that a Superior Titanium-coated Topstitch neelde only lost 25 microns due to abrasion compared to the 120 microns that the Chrome-plated (regular) needle lost. Titanium-nitride is 2.5 times harder than Chrome and 4 times harder than Nickel. (1 Micron is one-thousandth of a millimeter – I had to look it up too!)

Not only will the coating make the needles better for their job, but also the shape of the needle will assure you that the threads and stitches will give smoother results.

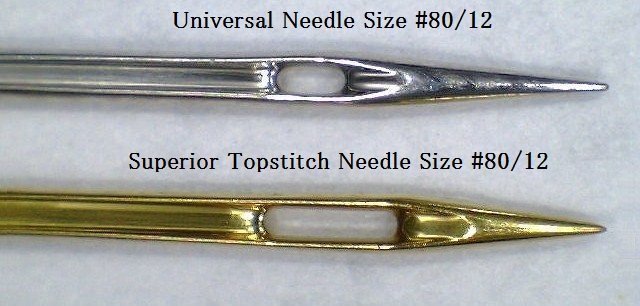

If you look at the picture above, you can see the eye of a (regular) machine needle: size 80/12. If you compare this with a topstitch needle, the eye of a universal needle is much smaller (the magnification is 40x). And look carefully: the upper left of the eye shows a burr! Such a burr will cause fraying and breaking of threads. Sometimes a burr is left after manufacturing, when a tiny piece of metal sticks out and is not smoothed (this can happen with all needles!).

If you look at the picture above, you can see the eye of a (regular) machine needle: size 80/12. If you compare this with a topstitch needle, the eye of a universal needle is much smaller (the magnification is 40x). And look carefully: the upper left of the eye shows a burr! Such a burr will cause fraying and breaking of threads. Sometimes a burr is left after manufacturing, when a tiny piece of metal sticks out and is not smoothed (this can happen with all needles!).

With Superior Toptstitch needles the eye is more elongated (almost twice the size compared to a regular needle), which gives the thread more space to move freely when being stitched. Less stress is put onto the thread at the point where the stitch is created, which in turn puts less friction on the thread.

With Superior Toptstitch needles the eye is more elongated (almost twice the size compared to a regular needle), which gives the thread more space to move freely when being stitched. Less stress is put onto the thread at the point where the stitch is created, which in turn puts less friction on the thread.

And lets take a look at the distance from eye to point: with universal needles, the distance is long, with Topstitch needles the distance is short: with the magnified picture above, you cannot see the eye from the universal needle,

And lets take a look at the distance from eye to point: with universal needles, the distance is long, with Topstitch needles the distance is short: with the magnified picture above, you cannot see the eye from the universal needle,

but with Superior Topstitch needle in the picture above, you can see the eye, because of that short eye-to-point length – less friction on the thread and the needle itself.

but with Superior Topstitch needle in the picture above, you can see the eye, because of that short eye-to-point length – less friction on the thread and the needle itself.

The picture above shows the difference again, between a universal needle and a Superior Topstitch needle, eye-to-point length. Both are 80/12 needles. Now you will understand why you can use any kind of thread with the Topstitch needle, even fragile ones like metallic threads. No friction, no problems. And yes, Superior Topstitch needles will fit in any type of domestic sewing machine (I haven’t heard of one where these needles didn’t fit).

Quite a story, but it gave me clarity about knowing which needle to use with this Crazy Colors Mystery Quilt 2017 project: a Superior Topstitch needle! Because I like to have one needle for every kind of thread I am using – it saves me time and effort, which I still need to change threads so often. Mostly I am working with size 90/14, but sometimes I will use size 70/10 for very thin threads, and the 80/12 for medium threads. And even if I forget to change the size of the needle, when the size 90/14 is in my machine, it doesn’t matters, because every thread fits in the large eye.

I hope this will answer a lot of questions, and you can take advantage with this information.

Happy Quilting!

Sylvia Kaptein

Sylvia’s Art Quilts Studio

www.sylviasartquilts.nl

[email protected]

Did you know that BERNINA has Topstitch needles too? Ask your local dealer! Check this: https://www.bernina.com/en-US/Products-US/BERNINA-products/Find-and-compare/BERNINA-needle-search and take a look at the video below:

(Pictures with permission/thanks to Bob Purcell of Superior Threads and different sources on the Internet)

* Everything that I have written here about needles, comes from 27 years of experience, but also from excperience from other quilters that have asked me questions through the years. This article is ment to give clarity about Topstitch needles: I do not have the intention to exclude other needles: just use what you like best).

Bewaren

BERNINA Corporate Blog -

BERNINA Corporate Blog -

hello. i am from poland. i uwielbiam was!

It was to show how a machine needle can wear, because not many people know this.

The electron microscope pictures are all of the same needle at the same tme, just with increasing magnification. They show that an apparently good needle can actually be damaged, leading to poor performance. I would guess that this damage was caused by hitting something hard such as a fastener,,or by dragging across an abrasive surface – if it was caused by normal wear I’d expect the tip would be less flat.